Probabilistic Physics of Failure and Fracture Mechanics Lab

Research Topics:

MTS Uniaxial Fatigue Testing Machines

- Two-post and Four-post machines rating at ±100kN in tension or compression under static and cyclic conditions.

- Fatigue Life Assessment Based on Energy Release

- Fatigue Crack Initiation Based on Entropy Generation

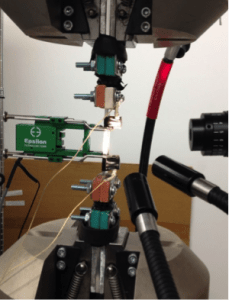

Optical Microscopy for Short Fatigue Crack

- 25 to 10X Microscope with C-mount adaptor for the video port. Simultaneous visual and video viewing.

- Short crack detection in fatigue

- Visualization of crack growth

Acoustic Emission Technique for Crack Initiation and Growth

- Sensors and amplifiers to collect and amplify the signals.

- Data acquisition module to perform front-end filtration and record the signals

- Software module to visualize the data and to perform the required analysis such as feature extraction and source location

- Assessment of crack initiation

- Large crack growth modeling

- Information entropy analysis of AE signals for crack initiation

- Thermodynamic entropy and information (Shannon) entropy as measures of damage in materials

- Acoustic emission signal analysis for extracting features sensitive to damage

- Acoustic emission features as precursors of damage

- Parametric approach and histogram-based approach to estimation of the acoustic entropy

Heating Chamber for Creep Testing

- Exposure of specimen under controlled heat up to 700oC

- Probabilistic modeling of creep

- Fatigue-creep testing capability

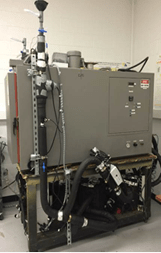

Corrosive Medium Chamber

- Probabilistic corrosion-Fatigue model development in piping.

- Probabilistic pitting corrosion in pipes

- Probabilistic stress corrosion in piping

- Environmental testing chamber with elevated temperature and salt spray to accelerate degradation

- Advanced condition monitoring

system to monitor diverse key performance indicators (i.e., temperature, flow rate, differential pressure, and conductivity).

system to monitor diverse key performance indicators (i.e., temperature, flow rate, differential pressure, and conductivity). - Vibration Monitoring and Acoustic Emission Monitoring systems to diagnose machine failures, continuously track health degradation, and predict remaining useful life of rotating machinery